How to Select A Mobile Gantry Crane?

How to select a mobile gantry crane? Check small gantry crane selection tips to get the right mobile gantry crane for your application. Small gantry crane tips for you!

The application of gantry crane

Mobile gantries are typically sold in standard configurations, but they can also be custom built and produced to meet the customer's individual application and specifications.

The dimensions of the gantry, which include the overall length, height, and width, as well as any obstructions or constraints that may apply, are one of the most important considerations you'll need to make. The span and effective length of the gantry, as well as the size and type of the load and its placement, are all equally important internal dimensions.

Portable gantries

The portable gantries are typically light-duty, making them best suited for routine maintenance or similar tasks. When compared to other gantry structures, their structure allows the operator to move more freely; however, this also means that the structure is less sturdy than 'A' Frame designs. A goalpost gantry would not be appropriate for a heavy-duty or frequent/regular application.

It's also worth thinking about if you'll require compact storage. A foldaway gantry is a solid recommendation if the goalpost gantry is used infrequently or needs to be transferred from site to site.

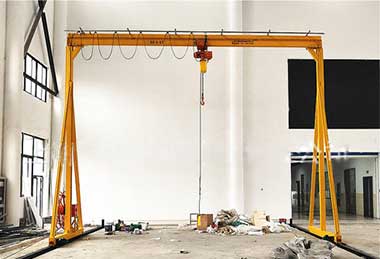

'A' Frane gantries

An 'A' frame gantry is designed for heavier-duty operations and applications where the structure will be constructed for an extended period of time. The construction is strong and should be considered for all general-purpose applications where big weights must be hoisted on a frequent basis, such as loading and unloading in yards/open areas or for usage in a workshop.

Adjustable height/foldable gantries

An adjustable height gantry would be most suited for applications where the runway beam must be varied in height.

A foldable gantry is suitable for applications where the structure will be utilized often but may need to be removed for transportation or storage on occasion.

Heavy duty or light duty gantry?

Applications where heavy-duty gantries should be considered include:

- The majority of the loads will be within the safe working load of the gantry (SWL),

- We'll employ either manual or powered lifting equipment.

- It is expected that the gantry will be used frequently.

You'll need a sturdy gantry construction.

Light-duty gantries can be used in situations like these:

- The majority of the loads will be below the gantry's safe working load (SWL),

- Manual lifting devices will be employed.

- It is appropriate to use a less resilient framework.

Type of bracing

Please contact our technical sales team to discuss your specific bracing needs, and we will provide you with recommendations.

Exteranal bracing

External bracing is appropriate for applications that require maximum internal clearance dimensions and have no external impediments. It enables for the most amount of movement along the runway as well as the lifting of large goods to their greatest height.

Internal bracing

Internal bracing is a possible choice in applications when there are external impediments, such as use over gangways or between machines, because it reduces the amount of travel down the runway.

Box bracing

A box braced gantry is a viable option in situations when maximum runway travel is required but external clearances are limited.

Rigid / spliced bracing

A rigid/ spliced braced gantry is an useful configuration for applications where maximal runway travel is required but external clearances are constrained.

Types of castors

The sort of castor to choose will be determined by the type of surface the gantry will be moved on, as well as whether the gantry is heavy duty or light duty. It's also worth thinking about if the wheels need to be fitted with brakes or whether the castors need to be supplied with rotating locks for safety.

Are jacks needed?

If your gantry is only going to be used for light duty work, jacks should be used to prevent the load from being supported by the castors. They're also advised for instances where the gantry must remain stationary for extended periods of time. They can also be used to assist in the leveling of a runway.

Brakes and locking devices

Brakes and locking devices are important safety considerations for any mobile gantry and are recommended where an inadvertent movement could occur, for example if the gantry is being used outdoors and wind unexpectedly moves the gantry from it's desired operational position. Brakes and locking devices can be fitted to most gantries and can be used alongside or as an alternative to a jack to prevent movement.

The use of brakes, wheel locks and castor rotational locks should always be considered where inadvertent movement might occur, e.g. outdoor due to high winds. They may be fitted to most types of gantry and used in addition to, or as an alternative to, jack to prevent movement.

Choosing a lifting appliance

Manual chain hoists and electric chain hoists are the most common alternatives for working with your gantry, and your decision will be based on how frequently the gantry will be used, the load type, and the planned working environment.

It's also vital to consider how the hoist will be attached to the gantry's runway beam, which can be done with a trolley, beam clamps, or fixed eyes, depending on how you want to utilize your gantry and hoist. You'll need to consider whether you have a suitable power source within your intended working space for electric chain hoists, and you'll also need to take the necessary precautions to avoid health and safety hazards, such as trailing leads or hoses, and restricting the gantry's movements to avoid tension on the power feed.

Keep in mind that the hoist you use with your gantry should only be used to lift loads that are rated to the gantry's safe working load (SWL).

Other factors to consider

- Other factors to consider while selecting a mobile gantry include:

- End stops will be required on the runway beam to prevent the trolley or cargo from colliding with the gantry supporting structure.

- The gantry, as well as its associated hoist and trolley, should be covered by the required documentation (EC Declaration of Conformity or report of thorough examination as appropriate).

- Although the surface over which the gantry will be moved will have been considered when selecting the castors or wheels, tiny objects, such as stones or metal offcuts, can wedge under wheels, necessitating extra caution. should stay away from these kinds of dangers

- The floor of your chosen work area should be able to withstand the pressure points exerted by the gantry's wheels, jacks, and other moving parts.

- Steel gantries are frequently delivered primed and painted as standard. Depending on the use, such as the food sector, alternative or additional finishing may be required to protect the loads being lifted/handled.

- Not all mobile gantries can move under load; if this is a need, please select one of our gantries that can. Hoist UK's written instructions must be rigorously followed when using any gantries that are capable of moving under weight.

- Where a gantry will be exposed to the elements during operation, it is advised that weather guards be installed to keep the runway track from corroding, as well as a rain cover and chain bag for the hoist.

Different types & configurations

Rolling gantry cranes are excellent choices for applications where you need a portable, movable and economical way for material handling at anywhere in your workshops or factories. To meet the various working requirements, portable gantry cranes are designed with different types and configurations are designed and it is important to find out the most suitable gantry crane designs for your particular applications.

In terms of crane production materials, the mobile gantry cranes can be grouped into steel small gantry crane and and aluminum portable gantry crane. The aluminum gantry crane is a lightweight gantry crane with high corrosion resistance. The selection of the steel or aluminum gantry cranes are decided based on your specific needs, such as, lifting capacity and lifting height etc.

Steel portable gantry crane with electric chain hoist

Aluminum gantry cranes with chain hoist

Steel gantry crane with electric wire rope hoist

- Rail mounted portable gantry crane - The rail type portable gantry crane are travelling on rail fixed on the ground for heavier loads handling. The rail type portable gantry crane is not so convenient to be moved and manipulated than the wheel mounted portable gantry crane with with higher lifting capacity. Track-mounted gantries is generally used for heavy loads handling over a fixed route, either manual or motorized.

- Wheel mounted gantry crane - With 360°rotation wheels, the wheel mounted portable gantry crane is easier to move with high efficiency. The mini roller gantry crane is extremely popular for material handling in small workshops and warehouses and other extensive applications.

Rail portable gantry crane

Wheel / caster portable gantry crane hand push travelling type

Wheel / caster portable gantry crane truss leg A frame gantry crane

Trackless motor driven caster mounted portable crane with motor driven

- Fixed height portable gantry crane - the lifting height and span of fixed portable gantry crane are fixed and cannot be adjusted as needed.

- Adjustable height portable gantry crane- the lifting height of the mobile gantry crane is adjustable based on application requirements, which is more flexible and widely applied in workshop or warehouses where loads is required to go through aisles, doorways, around obstacles, and over or under obstruction,or in welding and fabrication shop where the fixed or adjustable gantries need to hoist parts and equipment into position.

Fixed height portable gantry crane

Fix height portable gantry crane with motor hoist

Height Adjustable portable gantry crane with manual hoist

Height Adjustable portable gantry crane with electric chain hoist